Description

Customised Load Cells

Rinstrum has been partnering with a US load cell designer and manufacturer for custom load cells since 2010 to allow us to provide full measurement chain solutions. Below are a range of custom load cells that we are using with clients matching the load introduction and form factor with cabling and often custom electronics.

- Defined cable lengths and M12 cable preparation for easy maintenance

- Specific APPlication design or modified standard catalogue designs

- Custom form factor, load introduction and mounting

- Load cell matching

Benefits of Loadcell Matching

By factory matching the signal output and impedance of the loadcells in a process called mV/V/ohm calibration all loadcells come from the factory with equivalent signal outputs. Generally, this is an indicator of a high-quality load cell. This means that the loadcells can be connected in parallel directly. Most of the time, there is no need to corner balance the loadcells with trimming resistors in an adjustable junction box. This saves a significant amount of installation and service time and allows the interchangeability of the cells.

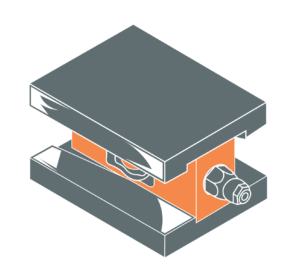

Planar Beam Load Cells

Planar beam load cells are commonly used in a number of weighing applications due to their low-cost and ease of styling for OEM applications. These are usually installed under a platform in sets of 3 or 4, in conjunction with a summing network. The low-profile construction of planar beam load cells makes them ideal for scale designs with limited space such as postal scales, retail checkout scales, or airport baggage scales.

They have the same footprint (mounting holes) with different capacities as you have to only change the outer dimensions.

Single Point Load Cells

Single point load cells have a horizontal flexure in the middle of the load cell body with strain gauges at the top and bottom that measure how much the metal bends when a load is put on it. They are called single point load cells because irrespective of where you put the weight, even if it is not directly over the load cell and thus forces a twisting, the reading is not affected. Typically, only one single point is used for the whole scale given the scale is not larger than around 600mmx600mm. There are many different types of single point load cells depending on how they are mounted and attached to the scales. Some applications include fishing boats, food preparation and mail rooms. These are mostly suitable for less harsh environments.

Triple Beam Load Cells

Triple beam Load cells have three horizontal flexures in the loadcell body with the top and bottom ones used to shunt side loads. Strain gauges are fitted to the center flexure. The main advantage of this architecture is that the top and bottom flexures create a type of parallelogram so that only vertical displacement forces are measured by the strain gauges. A great example of where this is important is conveyer belt weighing where the drag of the belt is a force that does not need to be measured. A triple beam cell allows for the forces from the belt to be taken by the top and bottom flexures leaving the center flexure to measure just the remaining force from the material on the belt. There are different types of triple beam load cells with overload protection, M12 connectors and can be hermetically sealed making them suitable for harsh environments. Having M12 connectors makes fault finding, maintenance and replacement of the load cells much more convenient and they can be connected to Rinstrum’s T720 transmitter to convert analog signals coming from the load cells to actual weight reading that can be used.

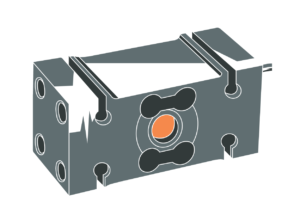

Tulip Load Cells

Configured with a full Wheatstone bridge, these load cells are installed into a machined hole on the structural legs of the tank or silo. These measure the distortion of the hole converting it into strain. They can be inserted at different angles to provide strain measurement for unusual load applications. LX03 Inserts make for a cost effective and simple installation on multi leg silos, where the accuracy of a traditional tank weighing assembly is not required.

Transportable vessels using Shear Beam Load Cells

Applications exist for weighing systems on transportable vessels where loadcells are mounted between the regular caster wheels and the frame of the vessel. Typically, four such loadcells are mounted on the vessel and are connected to conditioning electronics which is capable of delivering a stable weight signal to the control process. Such a system presents some unique challenges:

- moving a loaded vessel on casters with substantial impact and side loads

- the nature of the caster swivel means that the load introduction is off-center

- the system requires 4 high load capacity loadcells to deal with overload conditions during tank relocation but presents very low signal strength to the conditioning electronics. Overall system performance is determined by the stability of these electronics components.